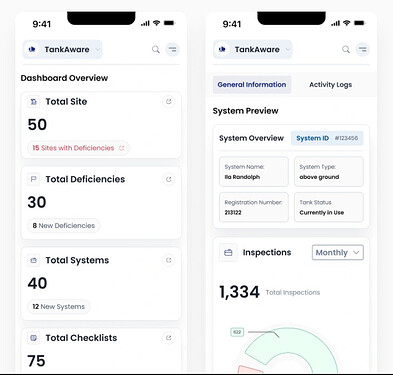

We recently deployed TankAware, an AI-powered platform designed to streamline petroleum site operations - eliminating inspection bottlenecks, improving field response, and automating coordination across vendors.

One of the core pillars of this project was Make.com, which allowed us to integrate automation into real-time operations without compromising reliability or speed.

How We Used Make.com

How We Used Make.com

Here’s how we embedded Make.com into the TankAware ecosystem:

![]() Slack Alerts

Slack Alerts

Site-level deficiencies or inspection failures trigger immediate alerts to relevant stakeholders via Slack, ensuring nothing is missed.

![]() Notion + Airtable Sync

Notion + Airtable Sync

Inspection data, task status, and daily logs are synced between Airtable and Notion for seamless collaboration between ops and compliance teams.

![]() Form Automation

Form Automation

Technician inspection forms (React Native frontend) are submitted and routed via Make.com to various workflows—assigning jobs, updating databases, and notifying supervisors.

![]() Maintenance Scheduling & Alerts

Maintenance Scheduling & Alerts

Preventive maintenance cycles are automatically triggered based on predictive AI outputs and usage patterns, ensuring equipment uptime.

AI + Automation Working Together

AI + Automation Working Together

By combining AI-driven insights (e.g., predictive maintenance, deficiency detection) with Make.com automations, TankAware empowers petroleum site managers to work smarter, not harder.

![]() 50% reduction in operational overhead

50% reduction in operational overhead

![]() 30% improvement in inspection accuracy

30% improvement in inspection accuracy

![]() Real-time coordination with zero manual routing

Real-time coordination with zero manual routing

Learn More: Full Case Study

Learn More: Full Case Study

Let us know what you’re working on - we’d be happy to share ideas, walk you through possible scenarios, or explore a hands-on collaboration.

![]() Book a call with our team OR Explore our work below

Book a call with our team OR Explore our work below ![]()